An Absolute Precision Engineering Company.

Contact Us Unit-2, Agarwal Industrial Estate no-6, Agarwal Naka, Sativali, Vasai(E)-401208. +91-9529037814 info@hexesindia.comOur state-of-the-art factory is home to a diverse range of specialized machines, each uniquely acquired to manufacture precision engineering components. By strategically loading these machines with specific jobs, we optimize our workflow and ensure exceptional results. From intricate details to complex parts, our machines work in harmony to deliver good quality and precision engineering solutions.

“Explore our facility and discover the cutting-edge technology that sets us apart."

A metal cutting bandsaw is an essential tool for anyone working with metal fabrication or metalworking. This machine uses a long, sharp blade with continuous teeth to cut through various types of metal efficiently and accurately.

A metal cutting bandsaw is a versatile and powerful tool essential for anyone involved in metalworking. By understanding the different types, key features, and proper maintenance, you can select the right bandsaw for your needs and ensure it performs efficiently and safely for years to come.

A drill machine, commonly known as a drill, is a versatile power tool used to create holes in various materials or drive fasteners. It is a staple in both professional workshops and home toolkits due to its wide range of applications.

A drill machine is an indispensable tool for a wide range of applications, from simple home repairs to complex construction projects. By understanding the different types, features, and proper maintenance, you can select the right drill for your needs and ensure it performs efficiently and safely for years to come.

A drill grinding machine is a specialized tool designed to sharpen and refurbish drill bits. Over time, drill bits can become dull and less effective, making it essential to sharpen them to maintain optimal performance. A drill grinding machine ensures precision sharpening, extending the life of your drill bits and ensuring they work efficiently

A drill grinding machine is a valuable addition to any workshop or tool maintenance setup. By understanding the different types, key features, and proper maintenance, you can select the right machine for your needs. Regular sharpening with a drill grinding machine ensures your drill bits remain effective and efficient, ultimately saving time and cost in the long run.

| X Axis Travel | 600 mm |

|---|---|

| Y Axis Travel | 400 mm |

| Z Axis Travel | 400 mm |

The Smart 6P, a high-speed powerhouse that revolutionizes precision manufacturing. With rapid traverse speeds of 48 m/min, this machine minimizes chip-to-chip time, maximizing efficiency and productivity. Its compact size belies its impressive capabilities, which include swift tool changes and an automated door, all designed to slash cycle times and make even the most complex jobs more cost-effective.

| X Axis Travel | 650 mm |

|---|---|

| Y Axis Travel | 450 mm |

| Z Axis Travel | 400 mm |

The CVM 640 that takes precision engineering to new heights. Equipped with advanced features for die and mold applications, this machine ensures unparalleled stability and surface finish, even on complex 3D contours. The Mitsubishi M80 controller, with its enhanced look-ahead capability, optimizes the machining process, resulting in exceptional surface quality and accuracy.

| X Axis Travel | 600 mm |

|---|---|

| Y Axis Travel | 600 mm |

| Z Axis Travel | 600 mm |

LMW J4, the latest addition. This innovative machine boasts a direct drive spindle, high RPM capabilities, and a spacious 600x600x600 travel size, all within a remarkably compact footprint. The LMW J4's cuboid design delivers exceptional rigidity, ensuring a superior surface finish. With its unique combination of power, speed, and agility.

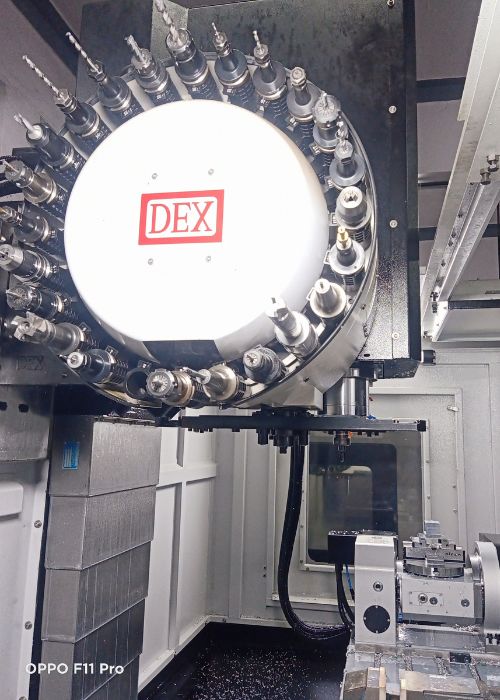

| X Axis Travel | 850 mm |

|---|---|

| Y Axis Travel | 550 mm |

| Z Axis Travel | 500 mm |

Cosmos 850 an advanced GSA 4-Axis table for complex component machining. Generous 180mm chuck diameter for increased versatility. Expanded Y-axis travel for larger workpieces. Automated chip conveyor for streamlined production. Mitsubishi controller for seamless operation and precision control.

| X Axis Travel | 1030 mm |

|---|---|

| Y Axis Travel | 600 mm |

| Z Axis Travel | 600 mm |

Kinematics 1060 features an advanced 5-Axis table add-on. This powerful combination enables the expert machining of intricate aerospace and medical components, leveraging automatic tool changers for seamless volumetric manufacturing. Enhanced multi-axis positional capabilities for complex geometries and Superior accuracy and precision in every detail

With the Kinematics 1060, we have pushed the boundaries of manufacturing excellence, delivering high-complexity components with increased productivity and precision. Experiencing the future of manufacturing

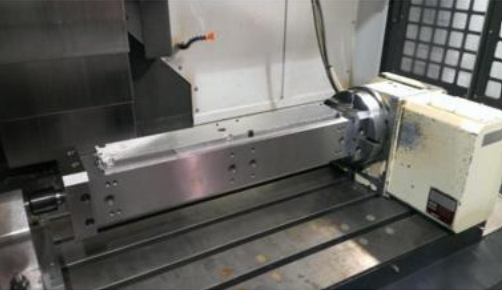

| Ø250 chuck |

|---|

| Length 300mm |

| 12 station turret |

| Thru coolant |

2 Axis CNC lathe for manufactruing turned components.

2 Axis CNC lathe for manufactruing turned components.